ON-LINE & OFF-LINE WASHING

Turbotect Saint-Petersburg Ltd. offers an integrated system for cleaning of the air inlet duct by using a technology combining off-line and on-line washing.

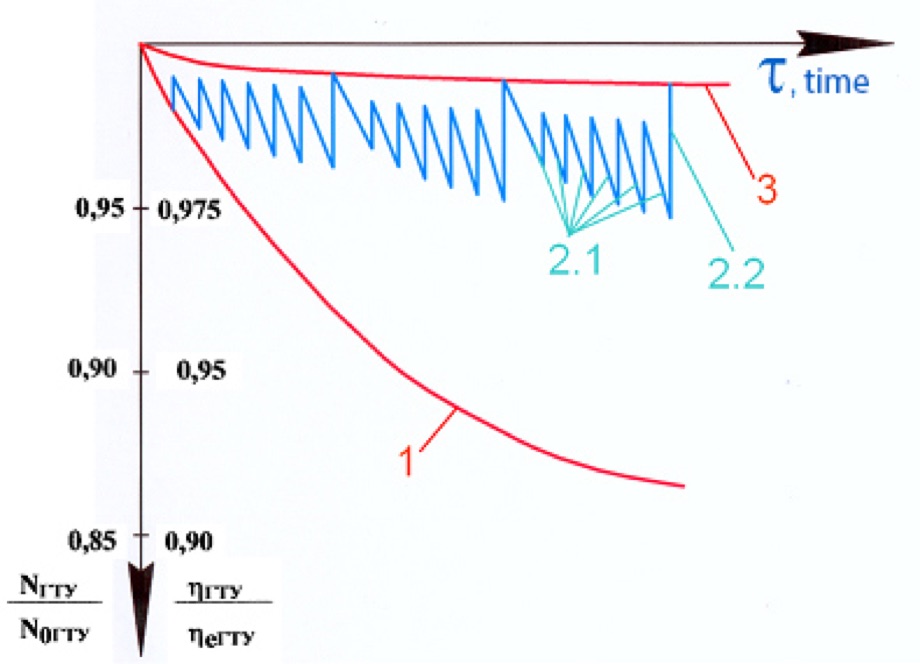

Off-line washing is performed after every 1500-2000 hours. During off-line washing, the gas turbine is idle and the rotor is rotated by a starter.

On-line washing is performed with the gas turbine in operation approximately every 200 hours and extends the intervals between off-line washes. Systematic and regular on-line washing allows the gas turbine characteristics (power and efficiency) to be maintained at a level close to nominal, the air inlet duct is kept clean and the power loss is reduced to a minimum.

COMPONENTS OF THE WASHING SYSTEM

The washing system by Turbotect Saint-Petersburg Ltd. consists of:

a set of nozzles (nozzles, supply hoses, headers, fasteners) for off-line washing

a set of nozzles (nozzles, supply hoses, headers, fasteners) for on-line washing

a TPM unit for the preparation and supply of the cleaning solution and water. The unit is connected to on-line and off-line washing nozzles.

SPECIAL FEATURES

The washing systems by Turbotect Saint-Petersburg Ltd. are custom calculated and designed. For each particular gas turbine a CFD calculation is performed according to our proprietary method, verified in our trial facility and tested on working gas turbines

Combined washing technology - off-line and on-line washing

Different types of nozzles for on-line and off-line washing with different designs, spraying angles, droplet sizes

Different nozzle installation patterns for on-line and off-line washing

Different TPM designs

Turbotect Saint-Petersburg Ltd. successfully cooperates with different gas turbine manufacturers. A compressor washing system therefore may be installed both at the manufacturer's plant (for new gas turbines) and on existing gas turbines (retrofit). Our engineers are ready to visit the customer's site to evaluate the technical feasibility of the retrofit and make a turnkey installation of the system.

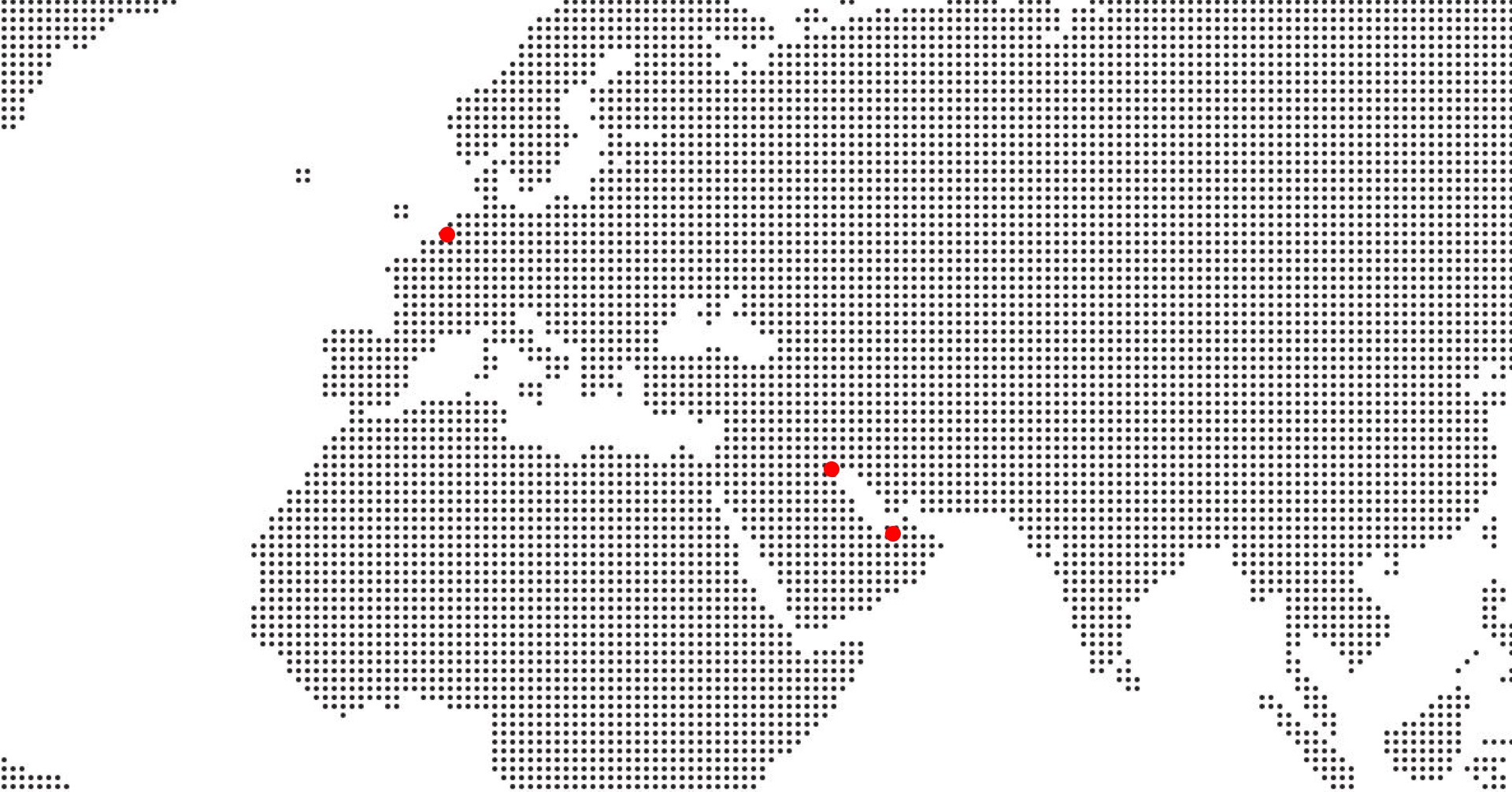

Washing systems by Turbotect Saint-Petersburg Ltd. are installed for cleaning stationary gas turbines at gas extraction, transportation and storage facilities, power generation plants as well as aircraft engines.

More than 1250 gas turbines from 2.5 to 160 MW have been equipped with washing systems supplied by Turbotect Saint-Petersburg Ltd. (GTU-2,5P, GTU-4P, GTU-6P, GTU-10P, GTU-12P, GTU-16P, GTU-25P, GTK-10I, GTK-25I, GTU-2,5P, GTD-4RM, GTD-6RM, GTD-8RM, GTD-6,3RM, GTD-10RM, GTD-110, DN80, DU80, DG90, DR59, DZh59, Al-31ST, GTK-10-4, GTNР-16, GT-750-6, MS5002E, GTE-160, GTE-65, D-336-2Т, NK-12ST, NK-14ST, NK-16ST, NK-36ST, NK-38ST, SGT-600, SGT-700, GTN-6Р, GTN-16).

Washing of a contaminated GT compressor helps to recover reduced efficiency and power by up to 5% and 10% respectively.

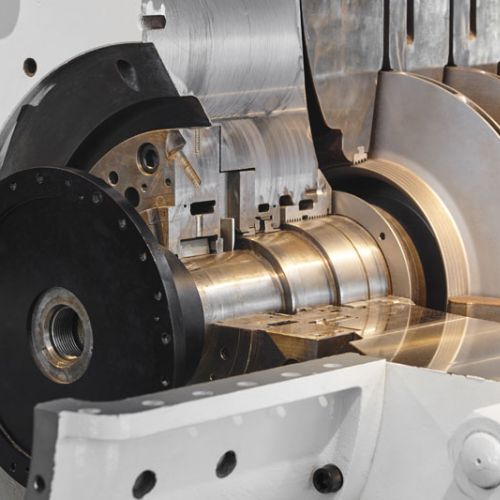

Operation of a nozzle for off-line washing

Nozzles Installed

Testing of a washing System