OME01-03 FEATURES:

Mobility, compact size

Possibility of strapping

Low energy consumption

Alarm system and main parameter monitoring

Option to operate the cleaner in stand-alone mode (connection to and disconnection from the oil supply system during turbine/machine operation)

Components in contact with oil made of stainless steel, oil- and petrol-resistant rubber

Quick-release leakage-free couplings for fast connection and disconnection of hoses

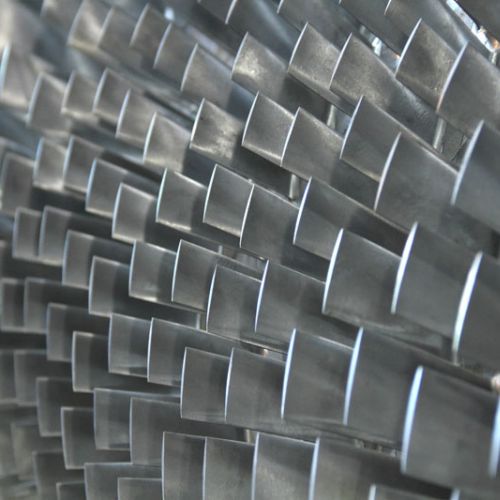

Different dielectric fluids cleaning

Oil ageing slowdown

| Length | mm | not more than 1600 |

| Width | mm | not more than 800 |

| Height | mm | not more than 1500 |

| Unit weight | kg | not more than 350 |

| Oil temperature | oC | 10-70 |

| Oil viscosity | cSt | 1-100 |

| Capacity | l/h | 500 |

| Purity class according to ROCT 17216; NAS 1638; ISO 4406 |

- | 6;3;-/11/9 |

| Water content | % | not more tahn 0.001 |

| Biological contamination | % | not more tahn 0.001 |

| Power supply | - | 380 V, 3 phase, 50 Hz |

| Maximum power requirement | kW | 1.5 |

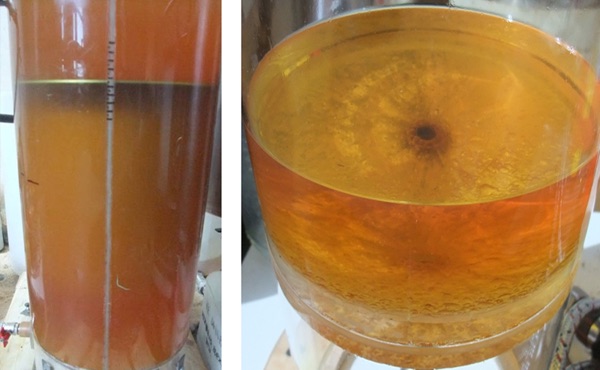

Residues of oil cleaning consisting of mechanical impurities (size over 5 µm) and dissolved water in the coalescence pre-treatment module

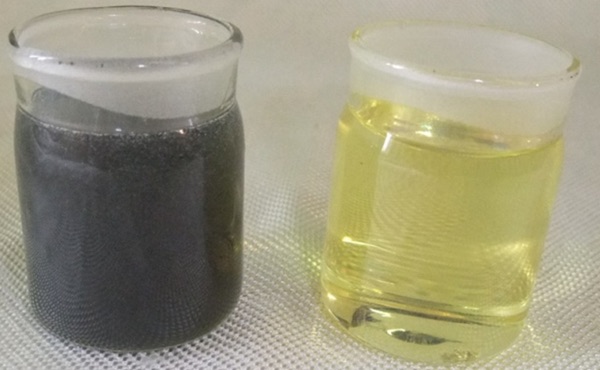

Result of cleaning oil of non-conductive impurities (corundum)

Result of cleaning oil of conductive impurities (carbon)