TSP-3030

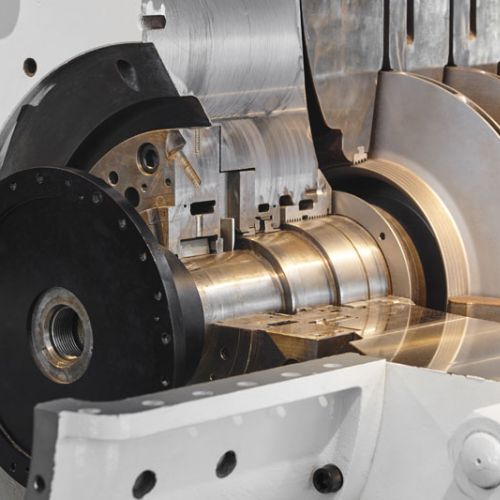

Water-based cleaner concentrate for on-line and off-line washing of axial compressors. ТSP-3030 has an extremely high cleaning efficiency comparable to solvent-based cleaners. In terms of chemical composition, ТSP-3030 is a unique biodegradable compound of non-ion-containing surfactants and emulsifiers dissolved in demineralized water. The product was specially developed for the removal of all known contaminants of gas turbines, where deposits usually form a solid combination of different salts, as well as municipal and industrial pollutants, carbohydrates and other carbonaceous materials. ТSP-3030 is a low-foaming product and can be used both cold and heated. Due to a careful selection of ash-free components, ТSP-3030 prevents the gradual contamination of the high-temperature section of a gas turbine and the content of non-volatile residue in the product is very low. TSP-3030 is suitable for cleaning all types of gas turbines and contains specially selected inhibitors to ensure the product's compatibility with aluminium, magnesium, nickel, nickel-cadmium, stainless steel, titanium and traditional coatings, including painted surfaces and elastomers. ТSP-3030 complies with the most stringent requirements specified by major gas turbine manufacturers.

ТSP-3030 has an extremely high cleaning efficiency comparable to solvent-based cleaners. ТSP-3030 quickly biodegrades in an aerobic aqueous medium.

TSP-5050

Solvent-based cleaner concentrate for on-line and off-line washing of axial compressors (for the removal of organic contaminants). TSP-5050 is a special compound of organic solvents, surfactants and emulsifiers for the removal of grease, oil, soot and other deposits that usually can form in a gas turbine compressor. Due to a careful selection of ash-free components, TSP-5050 prevents the gradual contamination of the high-temperature section of a gas turbine. TSP-5050 contains special inhibitors to ensure the product's compatibility with aluminium alloys, cadmium, magnesium and chromium alloys, nickel and nickel-cadmium alloys, stainless steel, titanium alloys and standard coatings of gas turbine components.

Concentrated solvent-based cleaner TSP-5050 for on-line and off-line washing of axial compressors (for the removal of organic contaminants).

TSP-A283

Anti-freezing agent for on-line and off-line washing of axial compressors at low ambient temperatures. TSP-A283 is a ready-to-use anti-freezing agent based on top-quality propylene glycol for axial compressor cleaning and flushing. Its formula was specially developed to be used in combination with ТSP-3030 (water-based cleaner) and ТSP-5050 (solvent-based cleaner) for both on-line washing (+10 °С to -10 °С) and off-line washing (+5 °С to -15 °С). TSP-A283 substitutes distilled water in a cleaning compound and is used for flushing (rinsing) the compressor after cleaning. In specific situations and subject to an appropriate injection system, TSP-A283 can also be considered as an anti-icing agent in regions with higher relative humidity at low temperatures (around 0 °С). TSP-A283 does not cause an increase of contamination in the high temperature section of a gas turbine. TSP-A283 is a ready-to-use, non-hazardous, non-toxic, biodegradable anti-freezing agent with a flash point of above 99 °С and a boiling point of 105 °С. Due to the high flash point, no special safety measures are required for storage and handling. There is also no need for special explosion-proof electric equipment.

TSP-A283 substitutes distilled water in a cleaning compound and is used for flushing (rinsing) the compressor after cleaning. Application temperature: +10 °С to -10 °С for on-line washing,

+5 °С to -15 °С for off-line washing.